Services

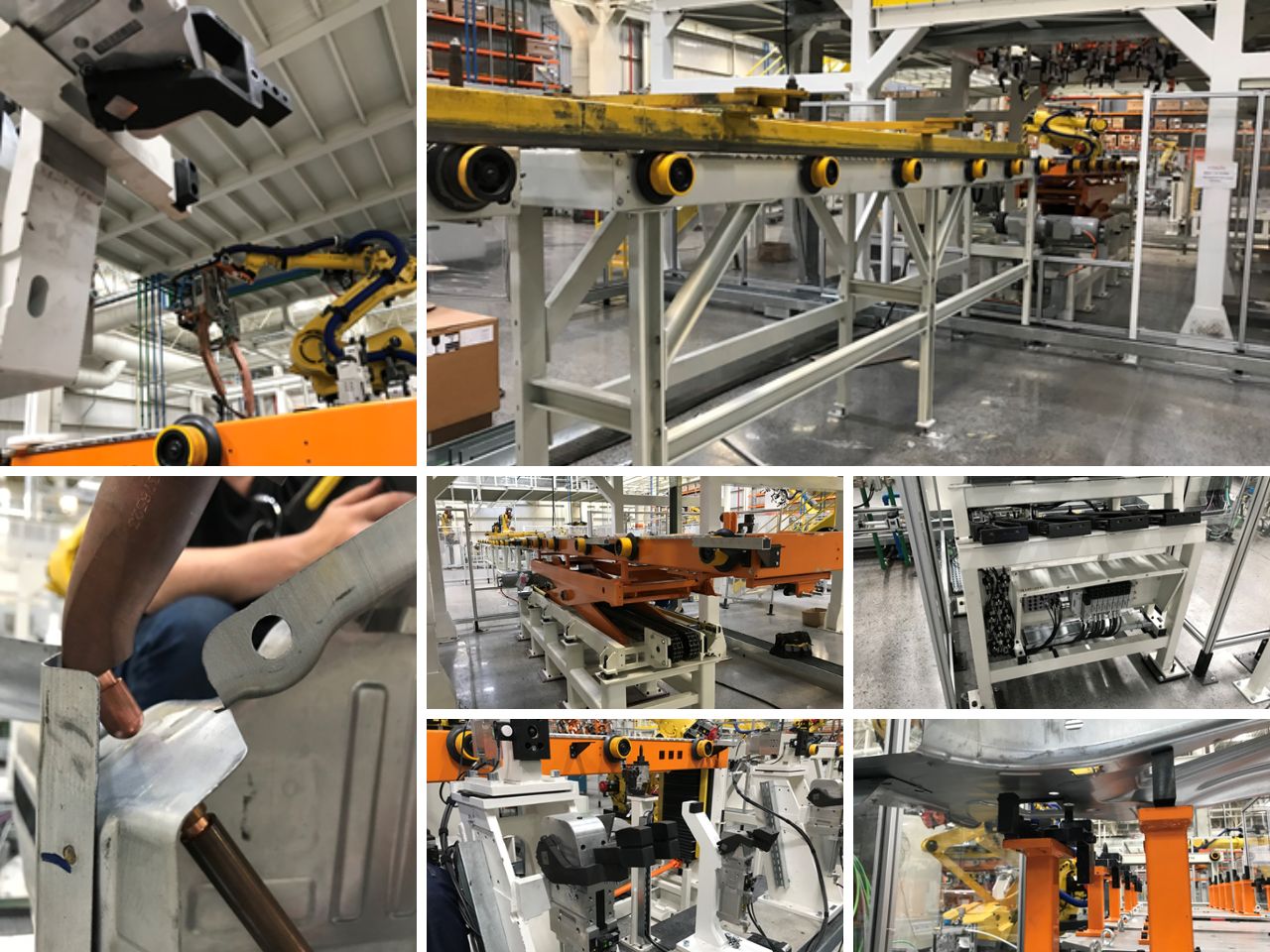

Manufacturing Services

GME’s manufacturing area is specialized in production of customized parts and equipment, from machining services to full assembly of equipment complete. GME guarantees, through its experienced team of specialists and robust processes, the quality desired by the customer.

- Tables

- Bases

- Supports

- Frames

- Robot Bases and Interfaces

- Metallic structures

- Pallets

- Racks

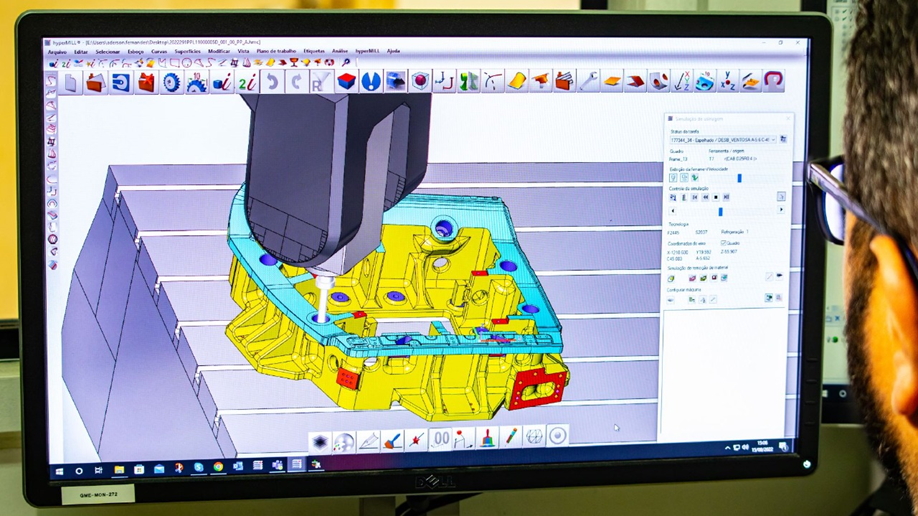

CAD/CAM machining programming service for complex surfaces and profiles. Dimensional and geometric quality assurance for parts.

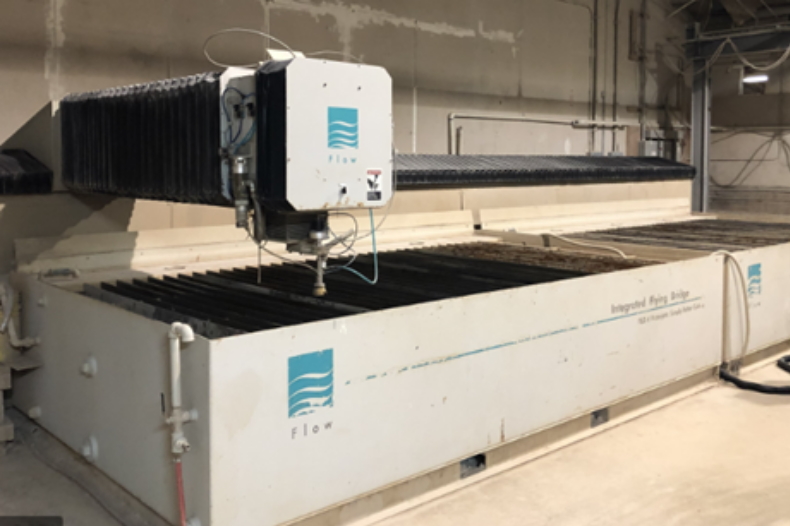

CNC Waterjet Cutting Equipment

- Cut up to 200mm thick

- Does not temper high carbon materials

- High productivity

Industrial painting is the most widely used anticorrosive protection technique to protect steel against corrosion. At GME, the painting process is carried out after blasting to ensure adherence. Subsequently, the base painting is done to ensure the paint anchorage in the final painting, which will provide protection against abrasion and chemical attacks, in addition to a pleasant aesthetic aspect.

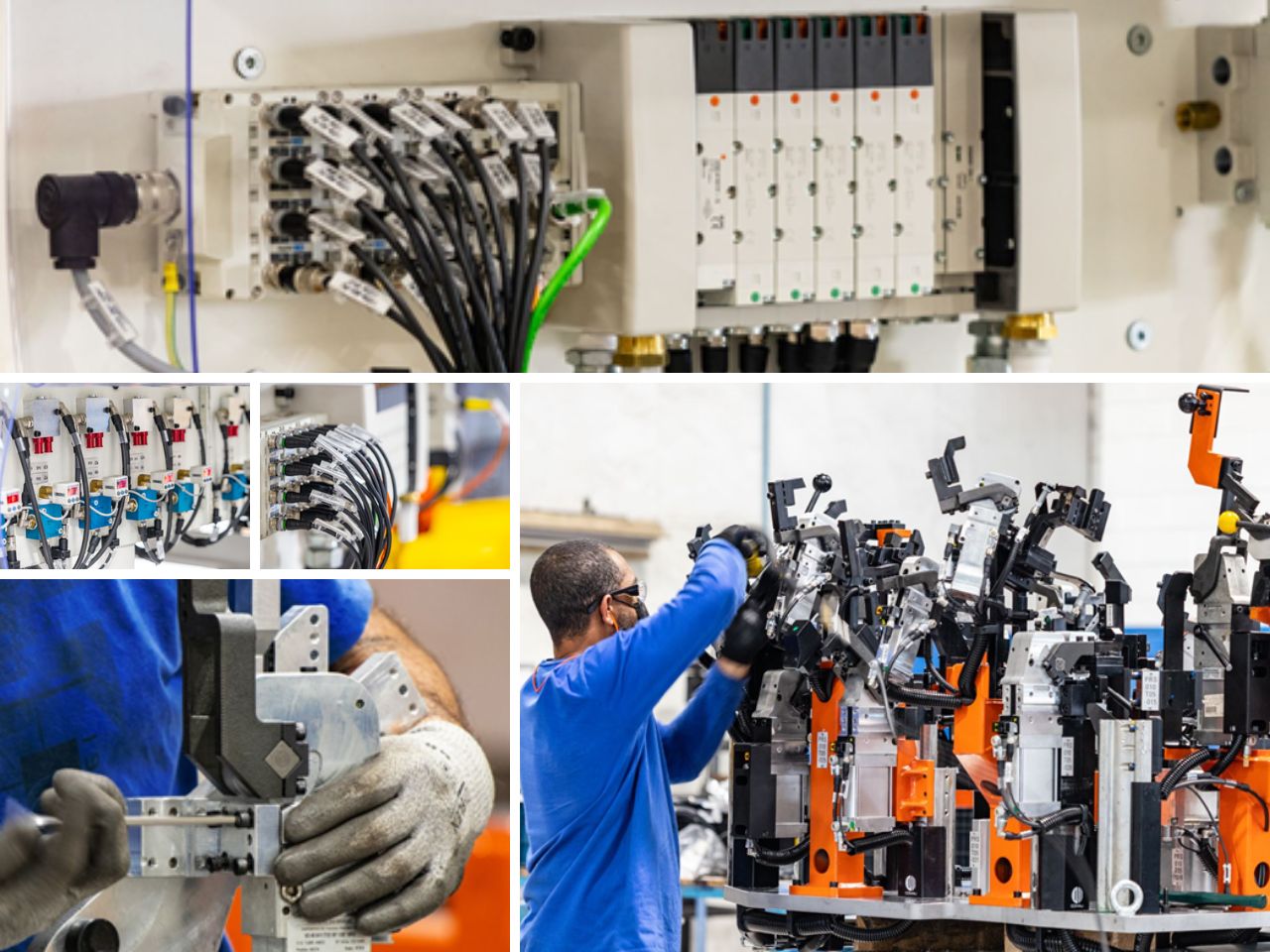

Assembly of special equipment, panels, pneumatic and fluidic systems.

- Quality inspection of manufactured parts

- Geometric certification

- Hardness certification of metallic materials

Equipment List:

- LASER API

- LASER LEICA

- POLI

- COORD3

- DUROMETER

Internal Structure to buy-off and try out internally.

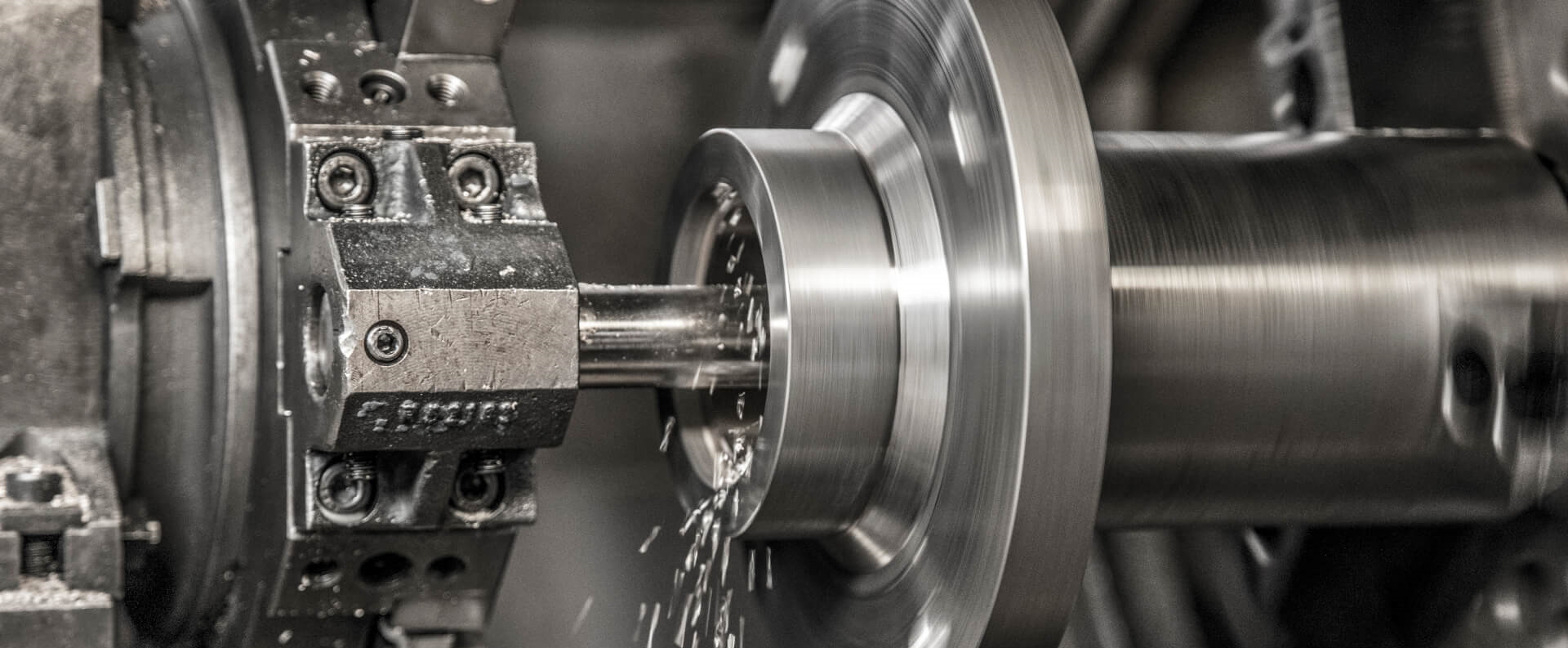

Machining Services

Services provided according to the needs of GME customer.

Custom machining parts:

- Up to 12 Tons

- Molds

- Stainless Steel Parts

Equipment list:

- ROMI

- LAZZATI

- CMS

- RAMBAUDI

- SUNLIKE

- FEELER

- DART MILLING MACHINE